Understanding VPD and Transpiration Rates for Cannabis Cultivation Operations

This article explores how vapor pressure differentials (VPD) affect transpiration rates in cannabis plants. Understanding of VPD at different temperatures and relative humidities, and its effect on this process, is important to gain maximum plant growth.

Photo © AdobeStock.com/openrangestock

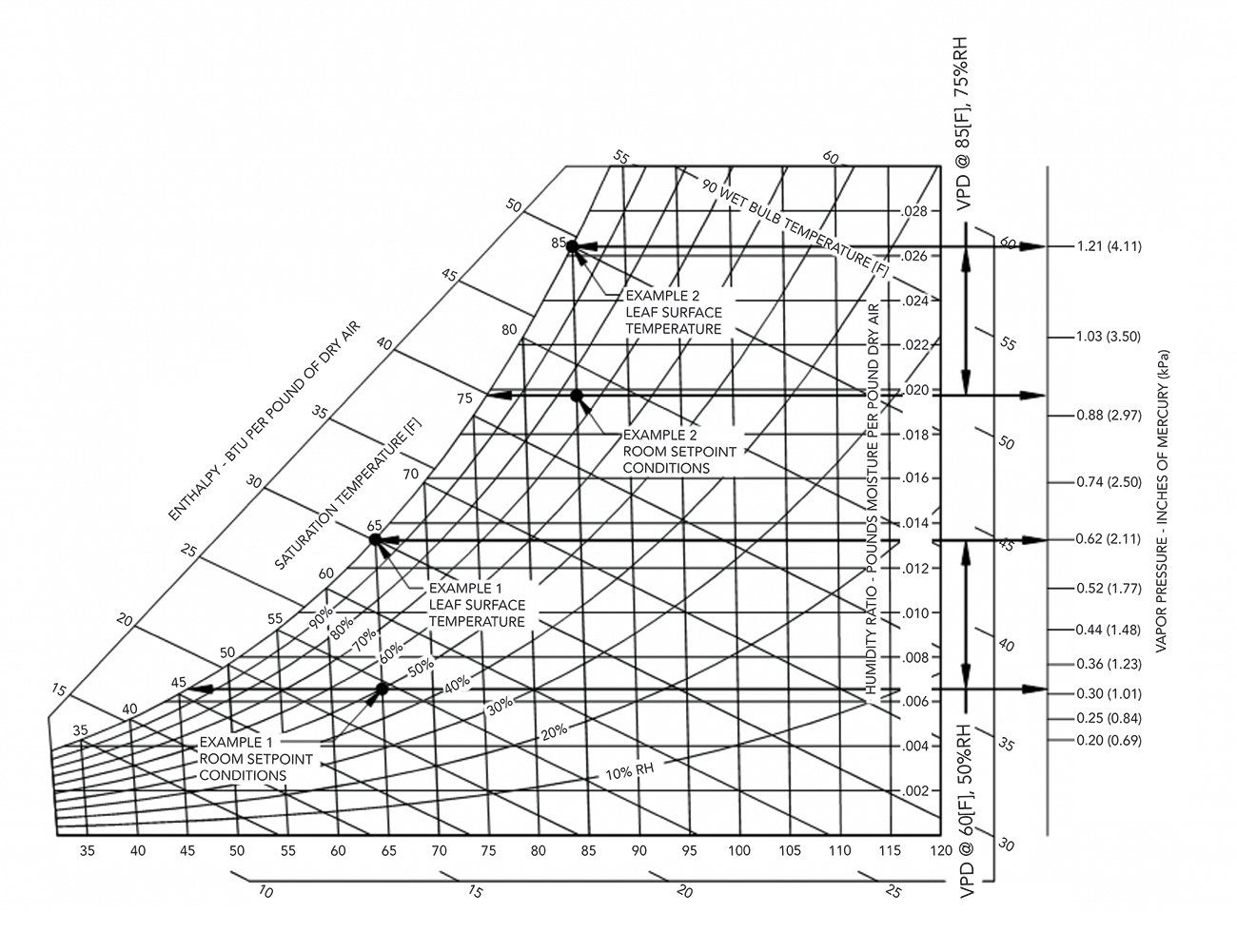

Figure 1: Example 1 and Example 2 both have similar VPDs, meaning transpiration and nutrient delivery between the two will be very similar. However, Example 1 has a much lower design temperature and relative humidity and will have a higher first equipment cost and a higher operating cost.

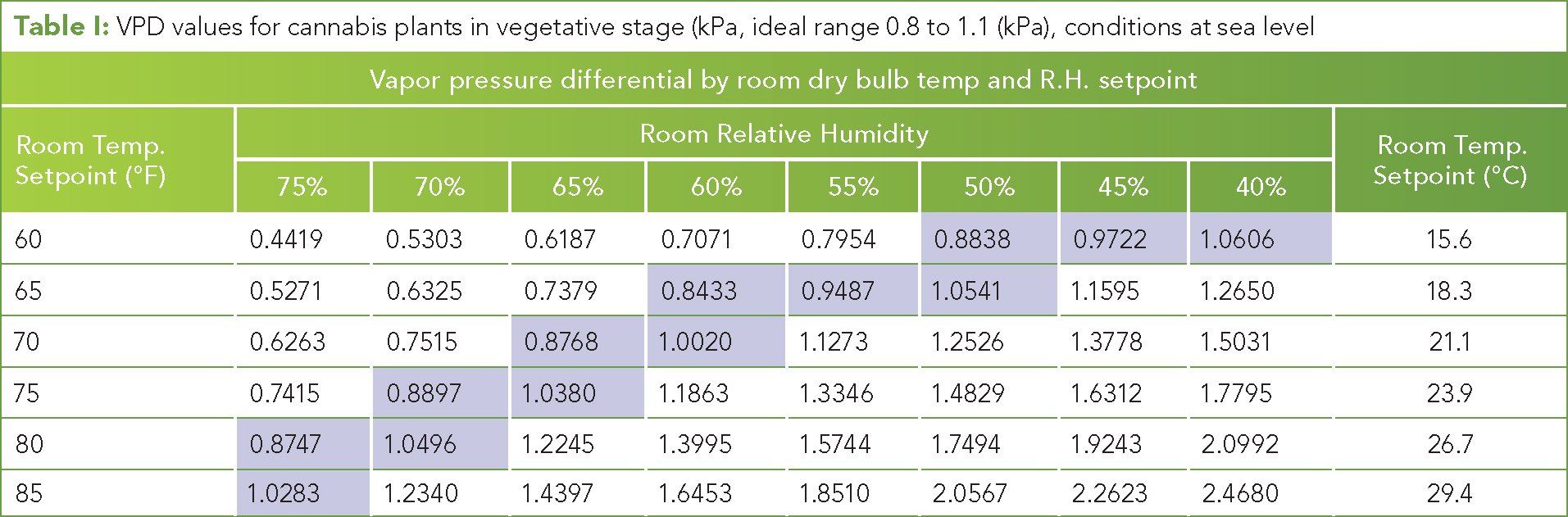

Table I: Vapor pressure differential by room dry bulb temperature and RH setpoint. Purple boxes indicate that the VPD is in the ideal range of 0.8 to 1.1 (pKa) for the vegetative state. Other boxes are outside the ideal range for the vegetative state.

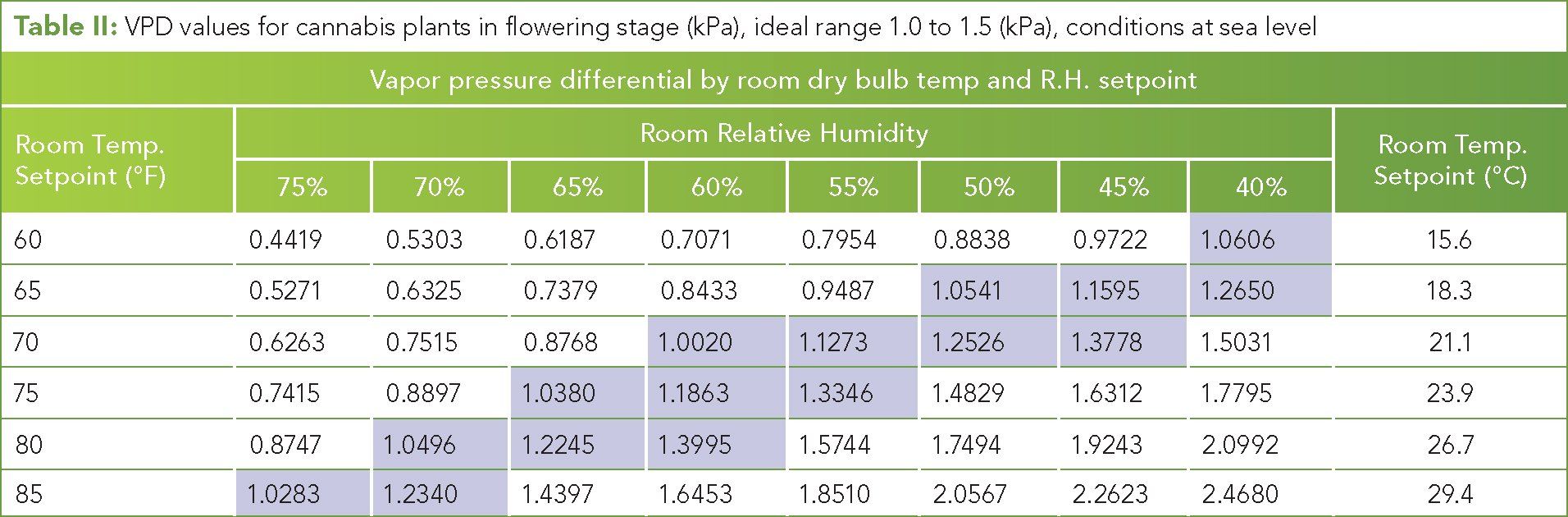

Table II: Vapor pressure differential by room dry bulb temperature and RH setpoint. Purple boxes indicate that the VPD is in the ideal range of 1.0 to 1.5 (pKa) for the flowering state. Other boxes are outside the ideal range for the flowering state.

This article explores how vapor pressure differentials (VPD) affect transpiration rates in cannabis plants. Transpiration is a process in which water and essential nutrients move through the plant from cell to cell. Understanding of VPD at different temperatures and relative humidities, and its effect on this process, is important to gain maximum plant growth. We also cover the impact of set points on growth environments as well as energy costs, along with an analysis on how data surrounding watering rates and transpiration can affect equipment selection.

We all learned about the water cycle in junior high-rain, evaporation, clouds, rain, and so on. This cycle takes on increased importance in the cannabis industry because maintaining the right space conditions for an indoor grow is essential to the success of a cultivation operation. Temperature and humidity play a large role in how cannabis plants will function, directly impacting both plant yield and overall quality. We must look beyond the simplified precipitation cycle and understand that space conditions directly affect a plant’s ability to sweat, or transpire.

A common misconception is that the transpiration of cannabis plants will affect the relative humidity within a grow room. In reality, that’s backwards-using the paradigm that the room conditions affect the plants’ ability to transpire rather than the plants’ transpiration affecting the room condition is a good perspective to have when reading this article. In an ideal setting, the room setpoint conditions (temperature and humidity) would be held perfectly stable and would never deviate regardless of what happens in the room. Keeping the room conditions perfectly stable is the job of the mechanical equipment used to control the environmental conditions of the room. If we can maintain any given set of room conditions, the question is: under what conditions does cannabis thrive?

As we will discuss, plant transpiration drives plant growth and vapor pressure differential (VPD) drives plant transpiration. Temperature and humidity both impact the vapor pressure differential, a factor that must be considered when making decisions about facility systems-especially when it comes to the tricky deliberations surrounding heating, ventilation, and air conditioning (HVAC) equipment selection. In order for plants to thrive in an indoor grow space, the VPD needs to be at a particular level, which can be different for every situation and every stage of growth. Since the temperature and humidity affect the VPD, the temperature and humidity both need to be at the correct levels-at the right “setpoint”-which means heat and moisture are going to need to be added or taken away from the grow room at different times.

Understanding the drivers behind this process is key to selecting the appropriate HVAC system for your operation. In our experience, a setpoint difference of just 10% can have a significant impact on HVAC system sizing, upfront cost, and ongoing energy costs. It’s worth exploring if a small difference in design setpoint will make a large impact on your HVAC system costs, without having much impact on the product yield of your operation.

Understanding VPD and Transpiration Rates

Temperature and humidity are defining factors for VPD, sometimes called vapor pressure deficit, which is what truly affects the health of a cannabis plant. Vapor pressure is the pressure at which liquid becomes a vapor. Here is a real-world example of vapor pressure in action: When you boil water on the stove, you heat the water, increasing the pressure to a point at which it reaches the vapor pressure of the atmosphere around it and becomes steam. In cannabis cultivation, VPD refers to the difference between vapor pressure within a plant and the vapor pressure of the air surrounding the plant. VPD is responsible for driving a process in the plant known as transpiration, which directly impacts plant health.

Transpiration is a process in which water and other essential nutrients move through a plant from cell to cell. It is also how plants regulate their own temperature and obtain the carbon dioxide they need out of the air. VPD drives transpiration and the nutrient uptake from the roots of a plant to the upper area of a plant. Water movement occurs as a result of plants releasing water vapor into the air through openings called stomata-almost as if they are sweating.

For More Cultivation Insights:

If VPD is too small, peak growth rates are not achieved, and problems like mold or root rot can become an issue. If VPD is too large, the plant stomata will close in an attempt to limit transpiration, which can result in issues like tip burn and leaf curl. VPD can be directly calculated from the temperature and relative humidity (RH) of both the plant and the grow room. Both of these concepts are explained in detail below. The surface temperature of the plant and the dry bulb temperature of the room are approximately the same, but since the plant has water forming, the plant surface will be at 100% RH when it is transpiring. For a given design temperature, we can modulate the VPD by changing the RH of the grow room.

A VPD range of 0.8–1.1 (kPa) is commonly known as ideal in the vegetative stage, while a VPD range of 1.0–1.5 (kPa) is commonly known as ideal in the flowering stage. Tables I and II show that the same ideal VPD range can be obtained at different temperatures and relative humidities.

To put it simply: Consistent temperature and relative humidity in the space --> consistent vapor pressure deficit --> plant transpiration --> plant growth.

This concept is further illustrated in Figure 1 on the psychrometric chart, which is a commonly used tool that graphically illustrates the relationship between air temperature and relative humidity as well as other properties.

What Are the Metrics?

As explained above, maintaining proper setpoints of indoor grow rooms is essential to the success of an operation, but what do we measure and how do we measure it? There are a few things to understand about measuring temperature and humidity and determining VPD:

- Wet and dry bulb temperature readings: Dry bulb temperature is the temperature reading most of us are familiar with; the temperature that is shown on the thermostat in a home. Wet bulb temperature is the temperature that a thermometer reads when its bulb is wrapped in a moist cloth. The wet bulb temperature indicates how much moisture is present in the air. When relative humidity is at 100%, the wet and dry bulb temperatures are equal. If the difference between the dry and wet bulb temperatures is small, there is a large amount of moisture in the air. There is so much moisture in the air that it is similar to having a wet rag around the thermometer bulb. If there is a large difference between the dry and wet bulb temperature readings, the air is dry.

- Relative humidity: Relative humidity (RH) is a measurement of the amount of moisture in the air expressed as a percentage of the maximum possible moisture in the air at a given dry bulb temperature. As humidity increases, the air of an indoor space will eventually reach a state of saturation. When air has reached its capacity for maximum possible moisture, water will leave the air in the form of clouds, dew, or condensation. In warmer temperatures, air is able to hold more moisture. If the amount of moisture in a space were to remain constant and the temperature increased, the RH would decrease. This is because the total amount of moisture present is the same, but it is possible for the air to take on more moisture, therefore the air is further from the maximum possible moisture, resulting in a lower percentage. Conversely, if the moisture content were to remain constant while the temperature decreased, the RH would increase because the moisture in the air is closer to the maximum possible moisture, resulting in a higher percentage.

Equipment Selection

The key to healthy VPD and transpiration rates is to provide controlled environmental conditions, which will come into play when you are selecting equipment for your operation.

The role of HVAC equipment is to keep the room as close to the design temperature and humidity setpoints as possible because this will have the greatest impact on the product. In the beginning of a project, we send an HVAC survey document to our clients to determine their project requirements. The information provided allows the engineers to determine the “design conditions,” which tells the engineer what they need to design around. Information such as temperature and humidity setpoints as well as type and quantity of lights, watering, and run-off rates are gathered.

This information allows the designer to estimate the transpiration rate of the plants and the heat load from the equipment, which are called latent and sensible loads, respectively. The HVAC equipment will remove the heat load and humidity load from the space, so the more accurate the information provided by the grower, the more accurate the sizing of the system will be.

Determining Transpiration Rates and Humidity Control Strategies

One of the best, most straightforward methods for determining transpiration rates is to use known watering rates to indirectly quantify transpiration. Once irrigation water is introduced into a space, it can do two things: stay within the plant or pot, increasing its overall mass, or leave the plant or pot as runoff or transpiration. The general assumption is relatively little of the water mass is left behind in the pot or plant, and the rest of the water is lost to runoff and transpiration between waterings. Quantifying watering rates is typically straightforward, but quantifying runoff can be difficult depending on which grow method is used. Data can be gathered at the grow facility level, stage of growth level, room level, or plant level.

Properly designed HVAC equipment will not only control the temperature of a space, but it will also remove the moisture transpired by the plants to keep the relative humidity ratio at the appropriate set point. There are numerous humidity control strategies. On the most basic level is the dehumidifier, which utilizes a refrigeration process to subcool the air to its saturation point to extract the moisture from the air. While effective, this is an inherently inefficient process as the compressor heat is rejected into the space, adding to the heat load that the HVAC equipment needs to take care of. On the most complicated level, your designer may add the dehumidification scheme into the overall HVAC design, whereby the air may be subcooled at the coils to extract the water out of the air, then the air may be reheated so as not to overcool the space. For maximum energy efficiency, the reheating of air can be done with hot water or hot gas produced by the heat rejected from the cooling equipment.

What happens when we vary the humidity and temperature setpoints? If the temperature and humidity setpoints are decreased, the peak load on the HVAC system increases, as does the energy required to run the equipment. Similarly, the reverse is true-if the temperature and humidity setpoints are increased, the peak load on the system decreases, and the energy required to run the equipment also decreases. It is in the best interest of the grower, both from a first cost and an operating cost perspective, to run their operation as hot and humid as possible.

Let’s refer back to Table II. As you can see, the calculated VPD at 70 °F and 60% RH is similar to the calculated VPD at 75 °F and 65% RH. Therefore, the plants may perform just as well at the higher temperature and humidity setpoint than at the lower temperature and humidity setpoint, but the effects on the first cost, physical size, and energy use of the HVAC system will be significant. In our experience, a setpoint difference of just 10% can have a dramatic effect.

Real World Case Study

The issue of equipment selection came to life in a recent project with very specific goals. Clients regularly come to us with specific temperature and humidity setpoints and ranges in mind. Often times these setpoints are determined by experience in the field, and not necessarily by gathering information on the VPD required. The growers know that their plants thrive in certain conditions, but normally they’ve determined this through a trial and error process. In this case study, our client-a cultivation and extraction facility-needed precise temperature and humidity control for their grow spaces, with a major focus on energy efficiency. Like most of our clients, they had specific temperature and humidity setpoints in mind: 76 °F and 55% RH.

The proposed HVAC system was a water-cooled chilled water system, with an economizer operation to allow for compressor-free operation when outdoor conditions allow. The hot water for the facility is provided via heat pumps that utilize the heat rejected from the chillers as the source for the heating loop. Fan coils inside the cultivation rooms utilize variable frequency drives to dehumidify without overcooling the spaces.

Because sustainability was a core goal of the client, we decided to start with a different approach-a shoebox energy model to narrow in on the implications of different setpoints on the size and energy use of the HVAC equipment. We were able to show the client that by adjusting their temperature and humidity setpoints upwards, they would be able to maintain the same VPD in the space, yet the size of the HVAC equipment decreased by 33% and the energy use associated with the HVAC equipment decreased by upwards of 35% per year. By looking at the VPD specifically, and using that metric to make decisions around the required temperature and humidity setpoint, we were able to design an HVAC system that met their sustainability goals and decreased the size of the equipment, while still ensuring that their plants would thrive.

The initial criteria the client provided us, a temperature setpoint of 76 °F and a relative humidity setpoint of 55%, would have resulted in an HVAC plant size of 600 tons of cooling. By looking first at the VPD, and then utilizing that to determine the setpoints, we were able to downsize the equipment to 400 tons of cooling. This equipment is roughly ¾ the physical size and 66% of the cost of the larger 600 ton system.

Final Thoughts

Proper HVAC equipment design --> consistent temperature and relative humidity in the space --> consistent vapor pressure deficit --> plant transpiration --> plant growth.

It is understood that proper HVAC equipment design is necessary to keep consistent temperature and relative humidity within a space. It is also generally recognized that the plant growth is impacted, both positively and negatively, by space temperature and humidity and therefore vapor pressure deficit. What is often overlooked or unknown is that small changes in temperature and humidity setpoints can have an imperceptible impact on the vapor pressure differential, and a large impact on the size, first cost, and operating costs of the HVAC system.

Disclaimer

We aren’t growers, we are engineers. As such, we do not claim to understand the complete effects of an operation running at higher temperature and humidity setpoints on plant quality and quantity. The purpose of this article is to illustrate the effects of temperature and humidity setpoint differences on HVAC sizing and energy costs, to allow growers to make a more informed decision when determining the appropriate setpoints for their space.

Laura Breit, PE, Michael Leavitt, PE, and Adam Boyd, PE, are professional engineers with Root Engineers in Bend, Oregon. Direct correspondence to: info@rootengineers.com.

How to Cite This Article

L Breit, M Leavitt, A Boyd, Cannabis Science and Technology 2(2), 52-61 (2019).

A Call for More Representative Horticultural Lighting Metrics for Cannabis Cultivation

March 5th 2025This article explores fundamental principles of photobiology, including Photosynthetically Active Radiation, photoreceptor-mediated responses, and the spectral influences on plant morphology and development.