A Brief Review of Derivatization Chemistries for the Analysis of Cannabinoids Using GC–MS

This article focuses on the use of GC–MS for the analysis of derivatized cannabinoids in hempseed oil matrix.

Determination of cannabinoid content in cannabis and cannabinoid products derived from cannabis and hemp is regulated in every jurisdiction where medicinal or adult use recreational programs have been legalized. A primary purpose of this testing is to quantify the total amount of psychoactive ∆9-tetrahydrocannabinol and other pertinent cannabinoids such as total cannabidiol, cannabinol, and cannabigerol content. High performance liquid chromatography with ultra-violet detection is the most common choice for the analysis. Gas-phase applications can also be used but the laboratory must determine if they will chemically modify (derivatize) the target cannabinoids or analyze them in their natural state. This choice affects sample preparation procedures and the analytical conditions of the gas chromatography (GC) system. This article focused on the use of GC–mass spectrometry (MS) for the analysis of derivatized cannabinoids in hempseed oil matrix. Sample preparation and synthetic conditions for silylation are discussed. Analytical results and observations of artifacts resulting from the derivatization processes and the analytical system are presented.

At least 70 known cannabinoids have been identified in Cannabis spp. (,). Nonetheless, state and country regulatory entities have focused on only a handful where medicinal or adult recreational use of cannabis or cannabinoid products has been legalized. These include ∆9-tetrahydrocannabinolic acid (THCA), ∆9-tetrahydrocannabinol (THC), cannabidiolic acid (CBDA), cannabidiol (CBD), cannabinol (CBN), and cannabigerol (CBG). The most common analytical procedure to identify and quantify cannabinoids in these products is high performance liquid chromatography (HPLC) with ultraviolet (UV) detectors. Typical HPLC-UV methods measure the cannabinoids listed above and 5–13 more that are commercially available as certified reference materials (CRM). Sample preparation for cannabis inflorescence is generally liquid extraction with methanol or ethanol followed by dilution. The sample preparation procedure for oils, concentrates, resins, and tinctures is simply dissolving the sample in methanol or ethanol which is again, followed by dilution. The purpose of dilution is two-fold: 1) contemporary cannabis, hemp, or cannabinoid products may contain 20–30% (wt./wt.) THCA, THC, CBDA, or CBD and dilution brings these concentrations into a µg/mL calibration range; and 2) dilution mitigates interferences from other endogenous chemicals, such as terpenes, that are commonly present in the 1–3% (wt./wt.) range.

Another common analytical methodology for the determination of cannabinoid content is gas chromatography–mass spectrometry (GC–MS). These analyses typically begin with a liquid extract of a sample that is injected into a hot inlet on the GC (commonly ≥250 °C). The liquid is volatilized, rapidly transferred through the inlet, and condensed onto the head of a chromatographic column. If this is performed properly, the condensed sample will form a tight band at the column head prior to traversing the column to perform the separation of the sample components (). With respect to cannabinoid analyses using GC–MS there are caveats that should be addressed. This work reviews GC–MS methodologies, the problems that can be encountered in various procedures, discusses derivatization chemistries with a focus on silylation of common cannabinoids, presents results, and examines artifacts in the data.

The Purpose for Cannabinoid Derivatization

Cannabis spp. which includes hemp, do not directly synthesize THC, CBD, CBN, or other neutral cannabinoids (). In the living plant, acid phytocannabinoids are biosynthesized. Post-harvest, these acids naturally decarboxylate to their neutral analogues upon exposure to light and heat. Acid phytocannabinoid decarboxylation also occurs in the hot inlet of a GC and in liquid chromatography–mass spectrometry (LC–MS) with electrospray ionization (ESI) in the negative ionization mode (). Furthermore, in the hot inlet of a GC, cannabinoid degradation products are formed. For example, under typical GC conditions about 70% of THCA converts to THC with the remaining 30% comprised of degradation products CBN and dihydrocannabinol ().

To avoid cannabinoid decarboxylation and degradation in GC methodologies, chemical derivatization is used. Chemical derivatization is a common procedure in GC analyses and serves several purposes. Firstly, derivatization caps polar or reactive moieties in a target analyte which improves chromatography and repeatability. Secondly, derivatization increases the volatility of the analyte rendering it more amenable to chromatography at lower temperatures (). Lastly, derivatization chemistries can be used to functionalize the analyte and make it more amenable to GC–MS using other ionization mechanisms such as negative chemical ionization (NCI). For example, estrogens and androgens were derivatized with pentafluorobenzoyl chloride and pentafluorobenzyl hydroxylamine for analysis with GC–tandem mass spectrometry (GC–MS/MS) using NCI. The formation of pentafluorobenzoyl esters and pentafluorobenzyl oximes afforded sub-pg/mL limits of quantitation (LOQ) for these analytes in serum (–11). Cannabinoids have also been functionalized for analysis by GC–MS using NCI, however, the derivatizing reagents and synthetic conditions must be carefully chosen to avoid undesired side-reactions and artifacts. The use of trifluoracetic acid anhydride (TFAA) and 1,1,1,3,3,3-hexafluoroisopropanol (HFIP) for the derivatization of THC and CBD was shown to convert CBD to THC and ∆8-THC (). This phenomenon was also reported when derivatizing with pentafluoropropionic anhydride (PFPA) and pentafluoropropanol (PFPOH) (). The conversion of CBD to THC has been determined to occur through an acid catalyzed stable carbocation intermediate (). It is therefore suggested that acidic reagents or reagents that become acidic upon storage like dichloromethane (DCM) are avoided when extracting and derivatizing cannabis and cannabinoid products.

Polarity

Functional moieties such as hydroxyls

(–OH), carboxyls (–COOH), and amines (–NH2) are polar and reactive. Their presence in a molecule adversely effects chromatographic peak shape on nonpolar or low-polarity column stationary phases. A common measure of polarity is total polar surface area (tPSA) and is measured in Å2. Total polar surface area is the surface area of oxygen and nitrogen atoms and their attached hydrogen atoms in a molecule and is an indicator of hydrogen bonding capacity (). Cannabinoids typically analyzed in testing laboratories are comprised of carbon, hydrogen, and oxygen and the functional moieties include alkanes, tetrahydropyrans, phenols, resorcinols, chromenes, and carboxylic acids. Figure 1 illustrates common fragments in cannabinoid molecules and their tPSA. Figure 2 is the chemical structure of THCA and some physicochemical properties including tPSA. The sum of the chromen-5-ol and benzoic acid tPSA equals the tPSA of THCA. This text will discuss how these are affected by derivatization.

Volatility

There is an observable and proportional relationship between boiling point and chromatographic elution times and an inverse relationship between boiling point and vapor pressure or volatility. In general, cannabinoids are high boilers, less volatile, and retained on a GC column until the oven reaches temperatures well over 200 °C.

The polarity of a molecule also affects its volatility because hydroxyls (–OH), carboxyls (–COOH), and amines (–NH2) are not sufficiently volatile. Derivatization addresses these issues by improving molecular volatility and decreasing hydrogen bonding.

Example: Derivatized Versus Underivatized Cannabinoids

A data-driven, untargeted analysis of six CBD oil pet supplements was performed using a GC-quadrupole time-of-flight (GC-QTOF) instrument (). The samples were analyzed without derivatization on a moderately polar DB-35MS UI column (35%-phenyl-methylpolysiloxane). Under the experimental conditions, the retention time for underivatized CBD was 13.47 min eluting at an oven temperature of approximately 295 °C. In another experiment, cannabinoids, including CBD, were derivatized with N-Methyl-N-(trimethylsilyl) trifluoroacetamide (MSTFA) capping both –OH moieties with trimethylsilyl groups and analyzed on a HP-5MS UI column (). In that work, the retention time of CBD was 12.55 min eluting at an oven temperature of approximately 295 °C.

In addition to the fact that in the underivatized form, cannabinoids should be analyzed with more polar columns, there are several points to note in this example. First, the polarity of CBD is reduced by derivatization making the molecule more volatile. Second, derivatized CBD has a calculated boiling point approximately 55 °C higher than underivatized CBD. And, finally, derivatized CBD elutes at an oven temperature equal to its underivatized counterpart yet its retention time was approximately 0.92 min earlier. This latter point is most interesting because the reduction in polarity of the derivatized CBD is expected to result in a longer retention time on the low polarity HP-5MS UI column (5%-phenyl-methylpolysiloxane) due to improved interaction with the stationary phase. However, this was not observed experimentally. Figure 3 illustrates CBD, its derivatized counterpart, and physicochemical properties for each including tPSA and boiling point in Kelvin.

Silylation of Cannabinoids

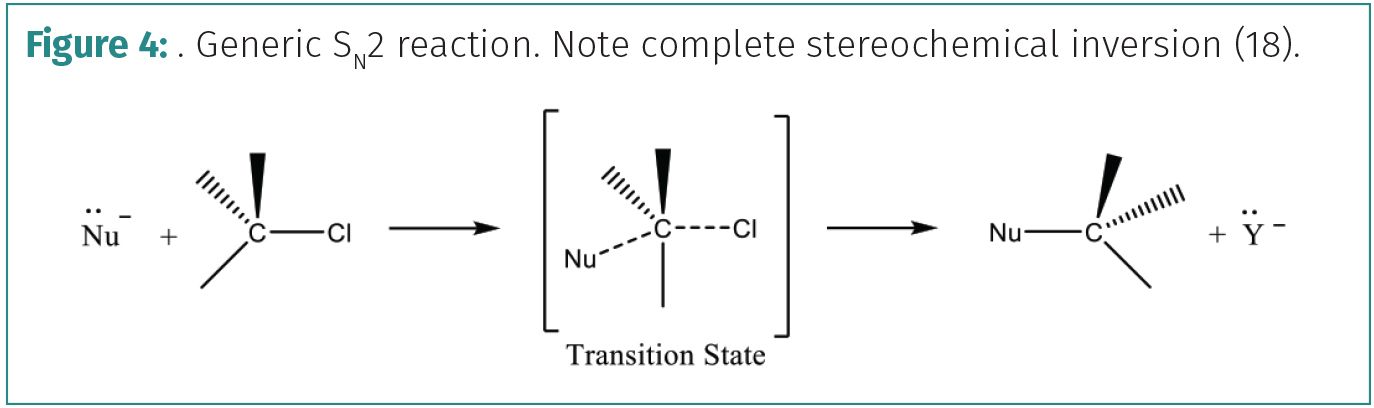

The mechanism of silylation is SN2 (bimolecular nucleophilic substitution) alkylation in which a nucleophile attacks the substrate opposite to the leaving group. This is shown for a generic reaction in Figure 4. Cannabinoids commonly analyzed in testing laboratories contain alcohols, phenols, resorcinols, and carboxylic acids. These react with silylation reagents to form chemical derivatives.

Sample Preparation

Cannabis inflorescence and hemp plant material are commonly extracted with solvents such as methanol and ethanol then further diluted prior to analysis. It is important to use high-purity commercial solvents and filter the extracts to remove particulate matter that may foul the analytical system. Solvents such as methanol and ethanol are protic, polar, and hydrophilic. SN2 derivatization chemistries are negatively impacted by these factors. Polar, protic solvents hydrogen bond with nucleophiles and slow reaction rates and the presence of water can hydrolyze silylation reagents leading to incomplete derivatization or no reaction at all (). The presence of water can also hydrolyze the derivative. Therefore, if derivatization will be performed, the extract will have to be dried down to remove problematic solvents and water prior to synthesis. Proper solvents for silylation are polar and aprotic, for example, ethyl acetate, acetonitrile, pyridine, or N, N-dimethylformamide (DMF) but care should be taken to ensure that these reagents are dry.

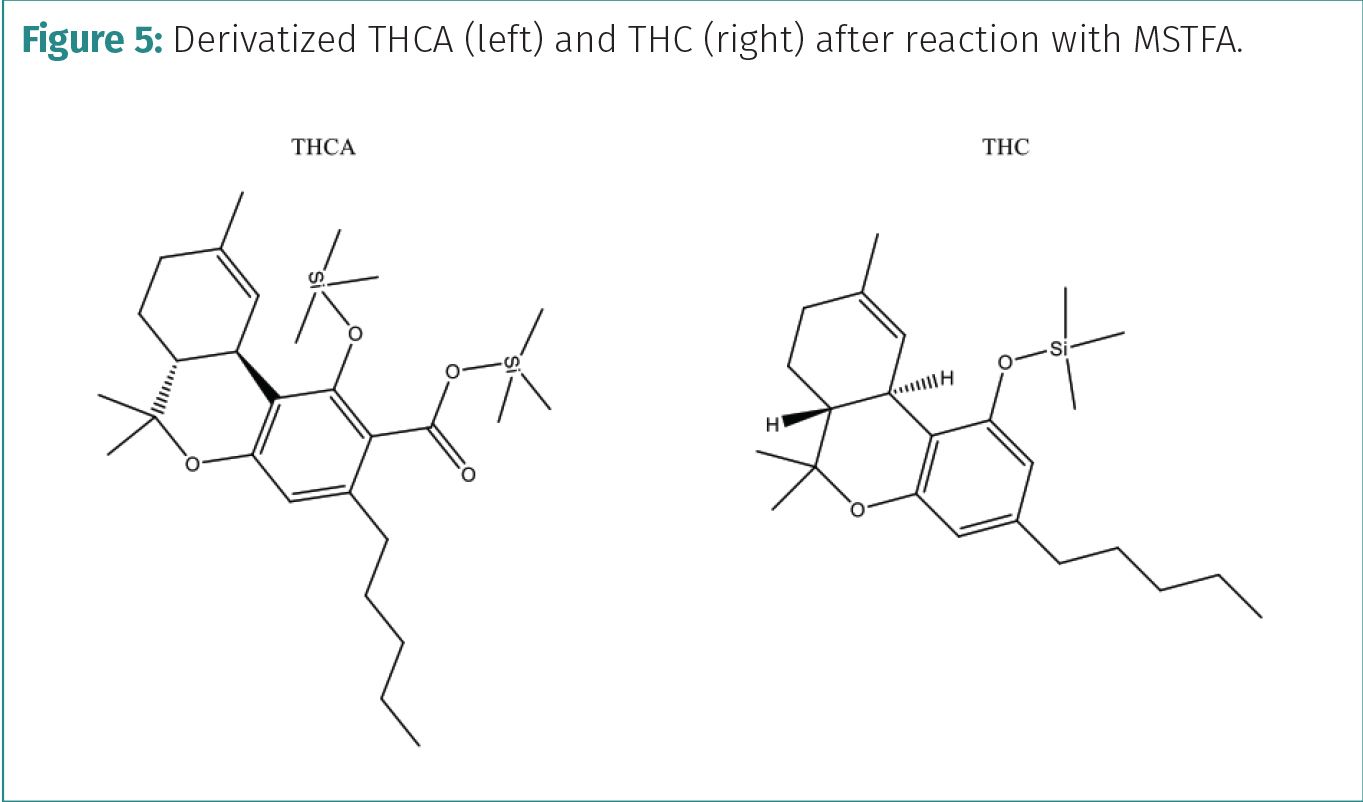

As an example of sample preparation and derivatization, consider an accurately weighed 0.2 g homogeneous sample of cannabis inflorescence (). To this, 20 mL high-purity methanol (P/N 5190-6896, Agilent Technologies) was added. The suspension was vortexed or shaken for 10 min to extract the cannabinoids, then centrifuged at 5000 rpm for 5 min. A 1.0 mL aliquot of the supernatant was filtered into a new vial with a 0.45 μm regenerated cellulose syringe filter (P/N 5190-5107, Agilent Technologies). To 10 µL of the filtered extract, 190 µL of high-purity methanol was added. The solution was briefly vortexed to mix and heated gently under nitrogen to dry. To the vial, 200 μL 10% (v/v) MSTFA in ethyl acetate was added. The vial was capped and heated at 60 °C for 30 min to derivatize. After cooling, the analysis was made directly from the vial. The chemical structures of silylated THCA and THC are shown in Figure 5.

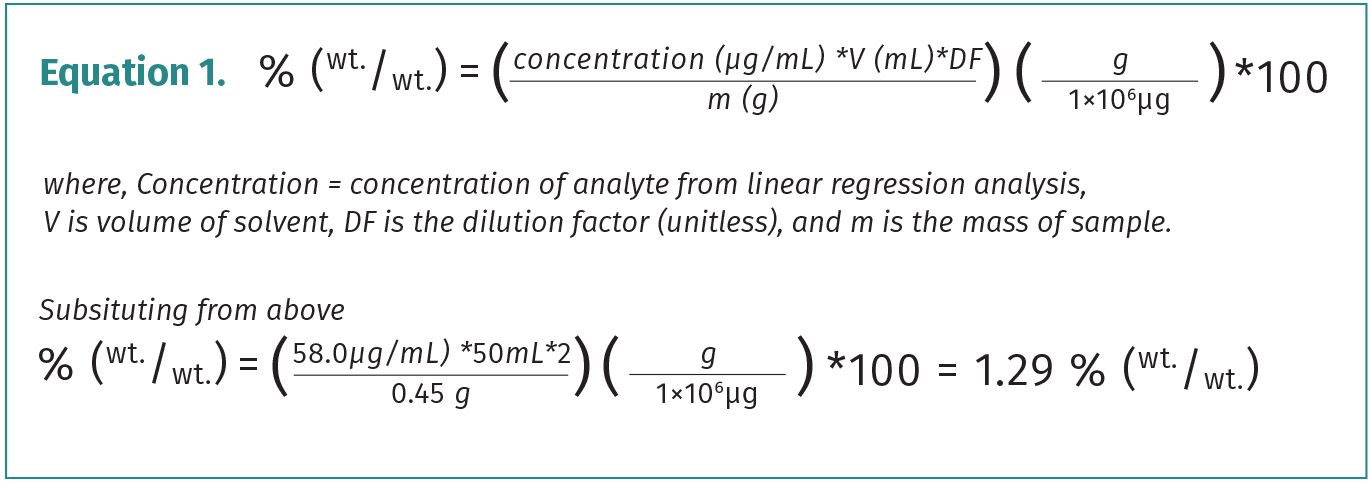

Oils, resins, and concentrates pose another problem. Although these sample types are commonly dissolved in solvents such as methanol and ethanol and diluted before analysis, drying these solvents down prior to derivatization results in the matrix being reconstituted in the sample container. In this case, polar, aprotic solvents that are miscible with the matrix should be used. The sample should be dissolved and diluted to the appropriate factor for analysis. Then, an aliquot of the sample is taken for derivatization. For example, a nominal 0.5 mL aliquot of a CBD oil was added to a 50 mL Class A volumetric flask. The weight of the sample was accurately determined to be 0.45 g. The flask was brought to volume with high-purity ethyl acetate and was not diluted further. A 1.0 mL aliquot of the solution was filtered into a new vial with a 0.45 μm regenerated cellulose syringe filter. A 200 μL aliquot of the filtered solution was transferred to a fresh auto-sampler vial and 200 μL 10% (v/v) MSTFA in ethyl acetate was added (this resulted in a 2-fold dilution factor). The vial was capped, vortexed briefly to mix, and heated at 60 °C for 30 min to derivatize. Upon analysis of the derivatized sample, the CBD content was determined from linear regression of a known calibration curve to be 58.0 µg/mL. To determine the percent by weight of CBD in the sample, Equation 1 was used.

GC–MS Spectra of Derivatized Cannabinoids

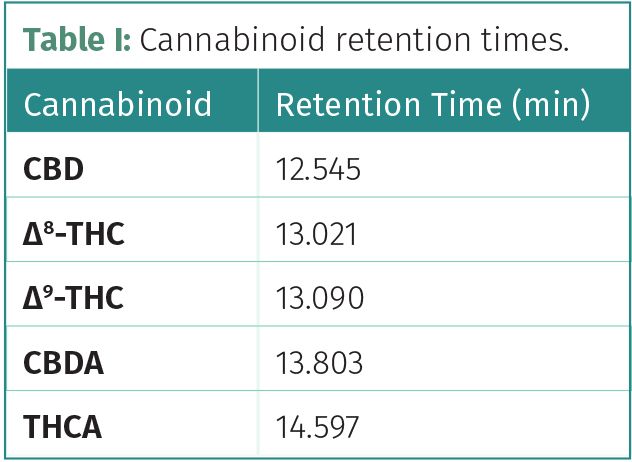

Organic hempseed oil was purchased from an online retailer. The material was screened using GC–MS in electron ionization (EI) mode and determined to be free of cannabinoids, terpenes, and residual solvents. ∆8-THC, ∆9-THC, THCA, CBD, and CBDA were spiked into the matrix and the matrix was dissolved in ethyl acetate and derivatized as described above. The derivatized samples were analyzed on an Agilent Intuvo 9000 GC – 5977B GC/MS system in EI mode using two low-polarity HP-5MS UI columns connected with a mid-column backflush flow chip. The oven was held at 70 °C for 1 min then ramped at 20 °C/min to 300 °C and held for 4 min. The MS was operated in scan mode over the mass range of 35 m/z to 600 m/z. The retention

times for the compounds are given

in Table I.

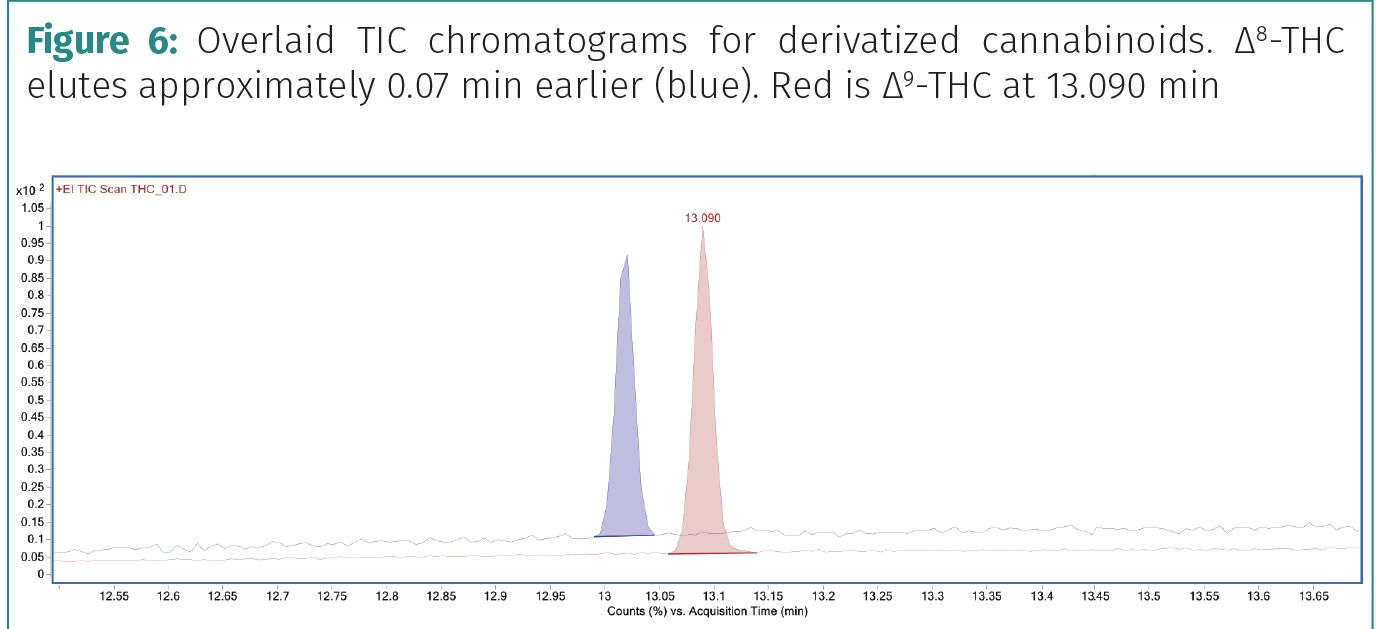

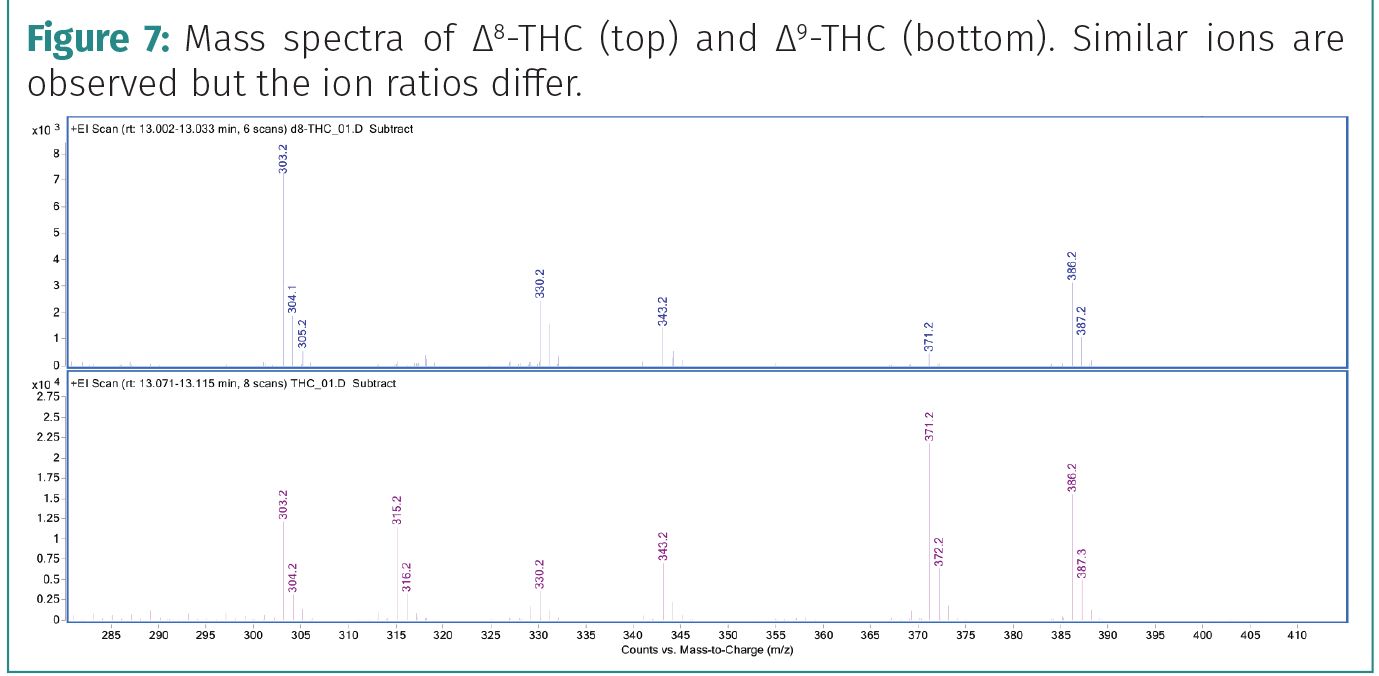

The extremely narrow peak widths of approximated 0.04 min were enough to chromatographically resolve ∆8-THC and ∆9-THC with baseline resolution. This is shown in Figure 6. The mass spectra for each are shown in Figure 7. The molecular ion at 386.2 m/z is observed for both isomers but the ion ratios of the fragments differ. Also observed is the M-15 ion (371.2 m/z), which is very common with trimethylsilyl (TMS) derivatives. Other common ions for TMS derivatives include 73 m/z (trimethylsilane) and 147 m/z (hexamethyl disiloxane).

GC–MS Artifacts

In this work, derivatization of cannabinoids with MSTFA as the silylation reagent yielded the desired products with no observation of partially derivatized compounds. The success of the derivatization is closely related to the synthetic conditions. The use of 10% silylation reagent in a GC “friendly” solvent such as ethyl acetate worked very well. Ethyl acetate is a hydrophobic, moderately polar, aprotic solvent commonly used in GC-based analyses. In conjunction with the derivatizing reagent, dilute solutions (0.5–1.0% v/v) of pyridine in ethyl acetate have been employed to both activate acidic protons and scavenge leaving groups like halogen ions. Other choices for silylation reagents would be N-O-bis-(trimethylsilyl)trifluoroacetamide (BSTFA) which is more reactive than MSTFA, especially if catalyzed with trimethylchlorosilane (TMCS). The same conditions used in this work with MSTFA can be employed with BSTFA.

It is important to use fresh solvents and to ensure that they are dry. Solvents to avoid include acetone, methanol, and ethanol. Dichloromethane (DCM) is often used in gas-phase analyses. It is hydrophobic, heavier than water with a polarity slightly higher than ethyl acetate. However, as DCM ages it becomes acidic as shown in Equation 2.

As noted above, the presence of mineral acids in solvents can cause CBD (and CBDA) to transform into THC (and THCA), respectively. Furthermore, DCM degrades over time. Therefore, stabilizers like amylene (2-methyl-2-butene) are added to DCM to scavenge free radicals created by degradation processes. These additives produce by-products (artifacts) that can be observed in the analysis and may interfere with the results ().

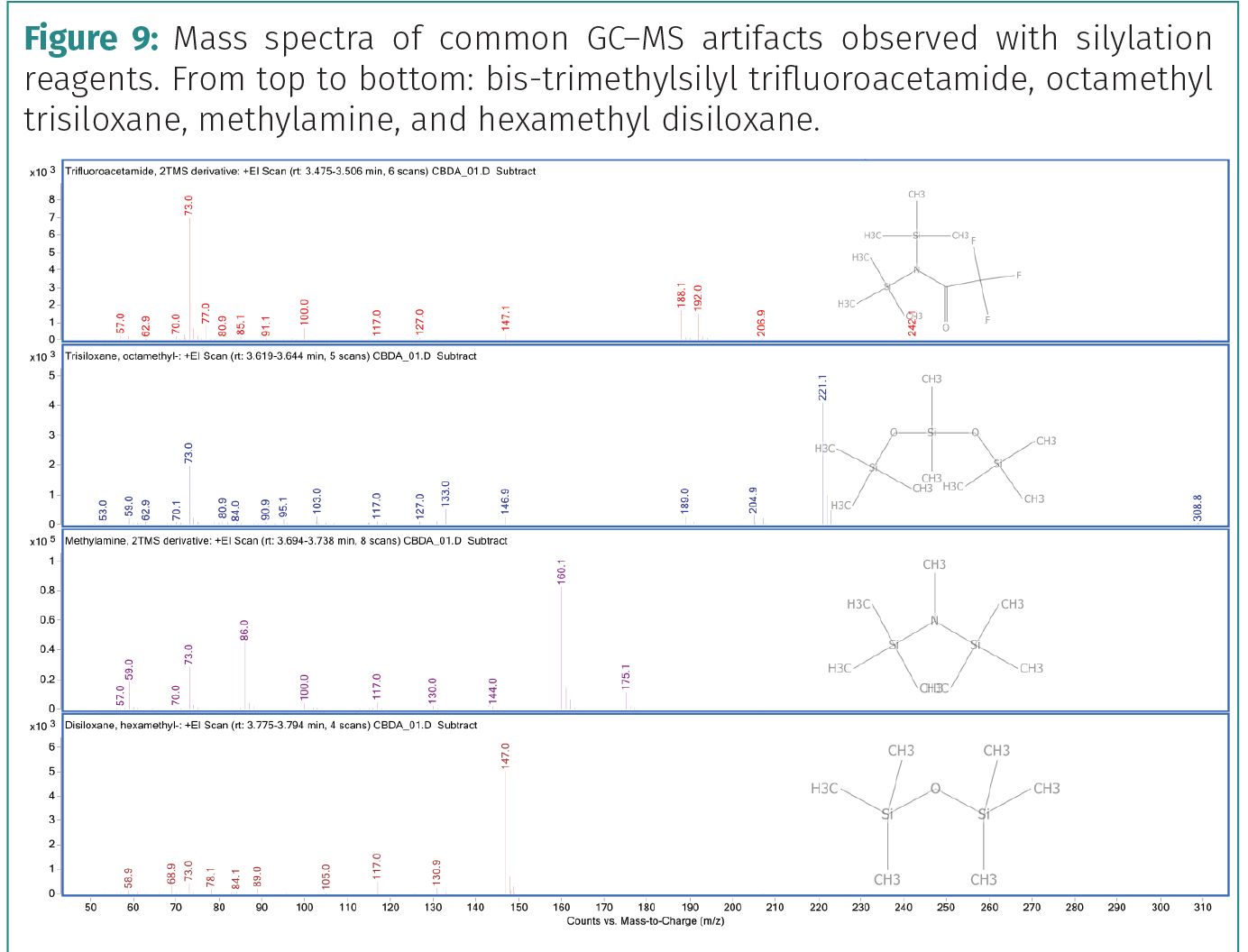

Silylation of carboxylic acids with MSTFA generally yields the desired derivative with few artifacts, but hindered phenols can yield mixtures of derivatized and underivatized products if not heated long enough or in the absence of a catalyst (). However, small artifacts are commonly observed in the mass spectra. Some of the artifacts are derived from the derivatizing reagent itself and others from the system or from handling system components such as septa or liners with bare hands. The chemical structure of MSTFA is given in Figure 8. Figure 9 shows the mass spectra of minor artifacts observed in the analysis.

Bis-trimethylsilyl trifluoroacetamide, octamethyl trisiloxane, methylamine, and hexamethyl disiloxane are by-products of MSTFA. Other common artifacts include the observation of 207 m/z, and 281 m/z (hexamethyl-cylcotrisiloxane and octamethyl-cyclotetrasiloxane, respectively) which are common column bleed and septum bleed ions. The latter often manifests as discreet, evenly spaced peaks in the chromatogram and the former manifests as a rising baseline as the oven temperature is increased. Trimethylsilyl palmitic acid and trimethylsilyl steric acid were also observed in this analysis. Their presence was most likely because of handling the septum without gloves or possibly from the hempseed oil matrix.

Conclusions

At the federal level in the United States, marijuana is still a Schedule I controlled substance and legalization occurs at the state level only. In Canada, medicinal and adult use recreational cannabis programs are legal and regulated by the federal government. Since the passage of the Farm Bill in the US, hemp has been legalized as an industrial crop and the United States Department of Agriculture (USDA) has been tasked with its regulation. As of June 2020, the USDA has only designated potency testing of hemp and require the analysis to be performed by HPLC or GC methodologies. Cannabis is differentiated from hemp based on the total psychoactive THC content with any material greater than 0.3 % (wt./wt.) being identified as marijuana (cannabis). At least one US state has stipulated potency testing to be performed by GC–MS. Elsewhere, it is at the laboratory’s discretion.

The analysis of cannabinoids in the myriad sample types available in the cannabis industry is of critical importance. From a safety point of view, THC or CBD content described on a product label must be quantitatively accurate. Where GC–MS is chosen as the analytical system, the laboratory must determine if they will perform the analysis with or without derivatization. This choice in turn affects the sample preparation procedures and the choice of analytical column stationary phase and conditions. If the laboratory choses to derivatize the cannabinoids, proper synthetic conditions need to be empirically determined to maximize derivatization efficiency and minimize artifacts that may interfere with the analysis. This work discussed the purpose and outcomes of derivatization, the synthetic procedures for silylation of cannabinoids including suggested solvents and ones to avoid, a proper column choice for derivatized cannabinoids, analytical conditions for the analysis, and examined the results and artifacts that may be observed.

References

- M.A. ElSohly and D. Slade, Life Sciences 78, 39–548 (2005).

- M.A. Huestis, Chem Biodivers 4(8), 1770–1804 (2007).

- L.M. Blumberg, Temperature-Programmed Gas Chromatography. (Wiley-VCH Verlag & Co. KGaA, Weinheim, 2010) pp. 7-13.

- A. Macherone, in Comprehensive Analytical Chemistry, I. Ferrer and M.E. Thurman, Eds. (Elsevier, Amsterdam, in press).

- P.W.J. Stone, S. D’Antonio, N.C. Lau, W.A. Hale, and A. Macherone, Cannabis Science and Technology 3(3), 34–40 (2020).

- F.E. Dussy, C. Hamberg, M. Luginbuhl, T. Schwerzmann, and T.A. Briellmann, Forensic Science International 149, 3–10 (2005).

- D.R. Knapp, Handbook of Analytical Derivatization Reaction (Wiley & Sons; New York, 1979) p. 10.

- A. Macherone, M. Churley, and R. White, Curr. Trends Mass Spectrom. 10-15 (2010).

- M. Churley and A. Macherone, "Highly Repeatable Ultra Low Detection of Estradiol Using Triple Quadrupole GC/MS in NCI Mode," Application Note 5990-5513. Agilent Technologies, Inc.(2010).

- A. Macherone, "Derivatization Procedure and Negative Chemical Ionization GC/MS/MS Conditions for the Analysis of Steroidal Analogs," Application Note 5990-9478. Agilent Technologies, Inc. (2015).

- A. Macherone and J. Stevens, "Extraction, Derivatization and Ultra-Sensitive GC/Triple Quadrupole Analysis of Estrone and Estradiol in Human Serum," Technical Overview 5991-5289. Agilent Technologies, Inc. (2016).

- R. Andrews and S. Paterson, J. Analyt. Toxicol. 36, 61–65 (2010).

- M.H.C. Chu and O.H. Drummer, J. Anal. Toxicol. 26, 575–581 (2002).

- T.D. Kiselak, R. Koerber, and G.F. Verbeck, Forensic Science International 308, 1-8 (2020).

- H. Pajouhesh and G.R. Lenz, NeuroRx. 2(4), 541–553 (2005).

- M. Curtis, S. D’Antonio, and A. Macherone, Cannabis Science and Technology 2(6), 48–52 (2019).

- A. Macherone, in Cannabis Laboratory Fundamentals, S. Opie, Ed. (Springer Nature, Switzerland AG. in press).

- F. Orata, in Advanced Gas Chromatography - Progress in Agricultural, Biomedical and Industrial Applications, M.A. Mohd, Ed. (IntechOpen Limited, London, 2012).

- S. Storm, M. Zumwalt, and A. Macherone, "Dedicated Cannabinoid Potency Testing in Cannabis or Hemp Products Using the Agilent 1220 Infinity II LC System," Agilent Application Note 5991-9285, Agilent Technologies, Inc. (2019).

- Millipore Sigma. Solvent Stabilizer Systems. Accessed June 7, 2020 from https://www.sigmaaldrich.com/chemistry/solvents/learning-center/stabilizer-systems.html.

- J.L. Little, J. Chromatogr. A 4(844), 1–22 (1999).

About the Author

ANTHONY MACHERONE is with Agilent Technologies, Inc. and the Johns Hopkins University School of Medicine.

Direct correspondence to:

anthony_macherone@agilent.com

How to Cite this Article

A. Macherone, Cannabis Science and Technology 3(7), 42-48 (2020).

Disclaimers

Agilent products and solutions are intended to be used for cannabis quality control and safety testing in laboratories where such use is permitted under state/country law.

The material presented in this article does not necessarily reflect the views and opinions of Johns Hopkins University or Johns Hopkins University School of Medicine

The author does not advocate the use of marijuana or cannabinoid products.

A Consumer Trends Survey of Minor Cannabinoids

March 6th 2025This survey assesses consumer awareness, usage patterns, and safety concerns with results indicating that cannabidiol (CBD), Δ8-tetrahydrocannabinol (Δ8-THC), and cannabinol (CBN) are the most frequently used cannabinoids, with vapes and edibles being the preferred methods of consumption.